One of the main reasons that we use alternating AC

voltages and currents in our homes and workplace’s is that AC supplies

can be easily generated at a convenient voltage, transformed (hence the

name transformer) into much higher voltages and then distributed around

the country using a national grid of pylons and cables over very long

distances.

The reason for transforming the voltage to a much higher level is

that higher distribution voltages implies lower currents for the same

power and therefore lower I2R losses along the networked grid

of cables. These higher AC transmission voltages and currents can then

be reduced to a much lower, safer and usable voltage level where it can

be used to supply electrical equipment in our homes and workplaces, and

all this is possible thanks to the basic Voltage Transformer.

A Typical Voltage Transformer

A Typical Voltage Transformer

The Voltage Transformer can be thought of as an

electrical component rather than an electronic component. A transformer

basically is very simple static (or stationary) electro-magnetic passive

electrical device that works on the principle of Faraday’s law of

induction by converting electrical energy from one value to another.

The transformer does this by linking together two or more electrical

circuits using a common oscillating magnetic circuit which is produced

by the transformer itself. A transformer operates on the principals of

“electromagnetic induction”, in the form of Mutual Induction.

Mutual induction is the process by which a coil of wire magnetically

induces a voltage into another coil located in close proximity to it.

Then we can say that transformers work in the “magnetic domain”, and

transformers get their name from the fact that they “transform” one

voltage or current level into another.

Transformers are capable of either increasing or decreasing the

voltage and current levels of their supply, without modifying its

frequency, or the amount of Electrical Power being transferred from one winding to another via the magnetic circuit.

A single phase voltage transformer basically consists of two

electrical coils of wire, one called the “Primary Winding” and another

called the “Secondary Winding”. For this tutorial we will define the

“primary” side of the transformer as the side that usually takes power,

and the “secondary” as the side that usually delivers power. In a

single-phase voltage transformer the primary is usually the side with

the higher voltage.

These two coils are not in electrical contact with each other but are

instead wrapped together around a common closed magnetic iron circuit

called the “core”. This soft iron core is not solid but made up of

individual laminations connected together to help reduce the core’s

losses.

The two coil windings are electrically isolated from each other but

are magnetically linked through the common core allowing electrical

power to be transferred from one coil to the other. When an electric

current passed through the primary winding, a magnetic field is

developed which induces a voltage into the secondary winding as shown.

Single Phase Voltage Transformer

In other words, for a transformer there is no direct electrical

connection between the two coil windings, thereby giving it the name

also of an Isolation Transformer. Generally, the

primary winding of a transformer is connected to the input voltage

supply and converts or transforms the electrical power into a magnetic

field. While the job of the secondary winding is to convert this

alternating magnetic field into electrical power producing the required

output voltage as shown.

Transformer Construction (single-phase)

- Where:

- VP - is the Primary Voltage

- VS - is the Secondary Voltage

- NP - is the Number of Primary Windings

- NS - is the Number of Secondary Windings

- Φ (phi) - is the Flux Linkage

Notice that the two coil windings are not electrically connected but

are only linked magnetically. A single-phase transformer can operate to

either increase or decrease the voltage applied to the primary winding.

When a transformer is used to “increase” the voltage on its secondary

winding with respect to the primary, it is called a Step-up transformer. When it is used to “decrease” the voltage on the secondary winding with respect to the primary it is called a Step-down transformer.

However, a third condition exists in which a transformer produces the

same voltage on its secondary as is applied to its primary winding. In

other words, its output is identical with respect to voltage, current

and power transferred. This type of transformer is called an “Impedance

Transformer” and is mainly used for impedance matching or the isolation

of adjoining electrical circuits.

The difference in voltage between the primary and the secondary

windings is achieved by changing the number of coil turns in the primary

winding ( NP ) compared to the number of coil turns on the secondary winding ( NS ).

As the transformer is basically a linear device, a ratio now exists

between the number of turns of the primary coil divided by the number of

turns of the secondary coil. This ratio, called the ratio of

transformation, more commonly known as a transformers “turns ratio”, ( TR ).

This turns ratio value dictates the operation of the transformer and

the corresponding voltage available on the secondary winding.

It is necessary to know the ratio of the number of turns of wire on

the primary winding compared to the secondary winding. The turns ratio,

which has no units, compares the two windings in order and is written

with a colon, such as 3:1 (3-to-1). This means

in this example, that if there are 3 volts on the primary winding there

will be 1 volt on the secondary winding, 3 volts-to-1 volt. Then we can

see that if the ratio between the number of turns changes the resulting

voltages must also change by the same ratio, and this is true.

Transformers are all about “ratios”. The ratio of the primary to the

secondary, the ratio of the input to the output, and the turns ratio of

any given transformer will be the same as its voltage ratio. In other

words for a transformer: “turns ratio = voltage ratio”. The actual

number of turns of wire on any winding is generally not important, just

the turns ratio and this relationship is given as:

A Transformers Turns Ratio

Assuming an ideal transformer and the phase angles: ΦP ≡ ΦS

Note that the order of the numbers when expressing a transformers turns ratio value is very important as the turns ratio 3:1 expresses a very different transformer relationship and output voltage than one in which the turns ratio is given as: 1:3.

Transformer Basics Example No1

A voltage transformer has 1500 turns of wire on its primary coil and

500 turns of wire for its secondary coil. What will be the turns ratio

(TR) of the transformer.

This ratio of 3:1 (3-to-1) simply means

that there are three primary windings for every one secondary winding.

As the ratio moves from a larger number on the left to a smaller number

on the right, the primary voltage is therefore stepped down in value as

shown.

Transformer Basics Example No2

If 240 volts rms is applied to the primary winding of the same

transformer above, what will be the resulting secondary no load voltage.

Again confirming that the transformer is a “step-down transformer as

the primary voltage is 240 volts and the corresponding secondary voltage

is lower at 80 volts.

Then the main purpose of a transformer is to transform voltages at

preset ratios and we can see that the primary winding has a set amount

or number of windings (coils of wire) on it to suit the input voltage.

If the secondary output voltage is to be the same value as the input

voltage on the primary winding, then the same number of coil turns must

be wound onto the secondary core as there are on the primary core giving

an even turns ratio of 1:1 (1-to-1). In other words, one coil turn on the secondary to one coil turn on the primary.

If the output secondary voltage is to be greater or higher than the

input voltage, (step-up transformer) then there must be more turns on

the secondary giving a turns ratio of 1:N (1-to-N), where N

represents the turns ratio number. Likewise, if it is required that the

secondary voltage is to be lower or less than the primary, (step-down

transformer) then the number of secondary windings must be less giving a

turns ratio of N:1 (N-to-1).

Transformer Action

We have seen that the number of coil turns on the secondary winding

compared to the primary winding, the turns ratio, affects the amount of

voltage available from the secondary coil. But if the two windings are

electrically isolated from each other, how is this secondary voltage

produced?

We have said previously that a transformer basically consists of two

coils wound around a common soft iron core. When an alternating voltage

( VP ) is applied to the primary coil, current flows through the coil which in turn sets up a magnetic field around itself, called mutual inductance, by this current flow according to Faraday’s Law

of electromagnetic induction. The strength of the magnetic field builds

up as the current flow rises from zero to its maximum value which is

given as dΦ/dt.

As the magnetic lines of force setup by this electromagnet expand

outward from the coil the soft iron core forms a path for and

concentrates the magnetic flux. This magnetic flux links the turns of

both windings as it increases and decreases in opposite directions under

the influence of the AC supply.

However, the strength of the magnetic field induced into the soft

iron core depends upon the amount of current and the number of turns in

the winding. When current is reduced, the magnetic field strength

reduces.

When the magnetic lines of flux flow around the core, they pass

through the turns of the secondary winding, causing a voltage to be

induced into the secondary coil. The amount of voltage induced will be

determined by: N.dΦ/dt (Faraday’s Law), where N is the number of coil turns. Also this induced voltage has the same frequency as the primary winding voltage.

Then we can see that the same voltage is induced in each coil turn of

both windings because the same magnetic flux links the turns of both

the windings together. As a result, the total induced voltage in each

winding is directly proportional to the number of turns in that winding.

However, the peak amplitude of the output voltage available on the

secondary winding will be reduced if the magnetic losses of the core are

high.

If we want the primary coil to produce a stronger magnetic field to

overcome the cores magnetic losses, we can either send a larger current

through the coil, or keep the same current flowing, and instead increase

the number of coil turns ( NP ) of

the winding. The product of amperes times turns is called the

“ampere-turns”, which determines the magnetising force of the coil.

So assuming we have a transformer with a single turn in the primary,

and only one turn in the secondary. If one volt is applied to the one

turn of the primary coil, assuming no losses, enough current must flow

and enough magnetic flux generated to induce one volt in the single turn

of the secondary. That is, each winding supports the same number of

volts per turn.

As the magnetic flux varies sinusoidally, Φ = Φmax sinωt, then the basic relationship between induced emf, ( E ) in a coil winding of N turns is given by:

emf = turns x rate of change

- Where:

- ƒ - is the flux frequency in Hertz, = ω/2π

- Ν - is the number of coil windings.

- Φ - is the flux density in webers

This is known as the Transformer EMF Equation. For the primary winding emf, N will be the number of primary turns, ( NP ) and for the secondary winding emf, N will be the number of secondary turns, ( NS ).

Also please note that as transformers require an alternating magnetic

flux to operate correctly, transformers cannot therefore be used to

transform or supply DC voltages or currents, since the magnetic field

must be changing to induce a voltage in the secondary winding. In other

words, Transformers DO NOT Operate on DC Voltages, ONLY AC.

If a transformers primary winding was connected to a DC supply, the

inductive reactance of the winding would be zero as DC has no frequency,

so the effective impedance of the winding will therefore be very low

and equal only to the resistance of the copper used. Thus the winding

will draw a very high current from the DC supply causing it to overheat

and eventually burn out, because as we know I = V/R.

Transformer Basics Example No3

A single phase transformer has 480 turns on the primary winding and

90 turns on the secondary winding. The maximum value of the magnetic

flux density is 1.1T when 2200 volts, 50Hz is applied to the transformer

primary winding. Calculate:

a). The maximum flux in the core.

b). The cross-sectional area of the core.

c). The secondary induced emf.

Electrical Power in a Transformer

Another one of the transformer basics parameters is its power rating. Transformers are rated in Volt-amperes, ( VA ), or in larger units of Kilo Volt-amperes, ( kVA ).

In an ideal transformer (ignoring any losses), the power available in

the secondary winding will be the same as the power in the primary

winding, they are constant wattage devices and do not change the power

only the voltage to current ratio. Thus, in an ideal transformer the Power Ratio is equal to one (unity) as the voltage, V multiplied by the current, I will remain constant.

That is the electric power at one voltage/current level on the

primary is “transformed” into electric power, at the same frequency, to

the same voltage/current level on the secondary side. Although the

transformer can step-up (or step-down) voltage, it cannot step-up power.

Thus, when a transformer steps-up a voltage, it steps-down the current

and vice-versa, so that the output power is always at the same value as

the input power. Then we can say that primary power equals secondary

power, ( PP = PS ).

Power in a Transformer

Where: ΦP is the primary phase angle and ΦS is the secondary phase angle.

Note that since power loss is proportional to the square of the current being transmitted, that is: I2R,

increasing the voltage, let’s say doubling ( ×2 ) the voltage would

decrease the current by the same amount, ( ÷2 ) while delivering the

same amount of power to the load and therefore reducing losses by factor

of 4. If the voltage was increased by a factor of 10, the current would

decrease by the same factor reducing overall losses by factor of 100.

Transformer Basics – Efficiency

A transformer does not require any moving parts to transfer energy.

This means that there are no friction or windage losses associated with

other electrical machines. However, transformers do suffer from other

types of losses called “copper losses” and “iron losses” but generally

these are quite small.

Copper losses, also known as I2R

loss is the electrical power which is lost in heat as a result of

circulating the currents around the transformers copper windings, hence

the name. Copper losses represents the greatest loss in the operation of

a transformer. The actual watts of power lost can be determined (in

each winding) by squaring the amperes and multiplying by the resistance

in ohms of the winding (I2R).

Iron losses, also known as hysteresis is the lagging of the magnetic

molecules within the core, in response to the alternating magnetic flux.

This lagging (or out-of-phase) condition is due to the fact that it

requires power to reverse magnetic molecules; they do not reverse until

the flux has attained sufficient force to reverse them.

Their reversal results in friction, and friction produces heat in the

core which is a form of power loss. Hysteresis within the transformer

can be reduced by making the core from special steel alloys.

The intensity of power loss in a transformer determines its

efficiency. The efficiency of a transformer is reflected in power

(wattage) loss between the primary (input) and secondary (output)

windings. Then the resulting efficiency of a transformer is equal to the

ratio of the power output of the secondary winding, PS to the power input of the primary winding, PP and is therefore high.

An ideal transformer is 100% efficient because it delivers all the

energy it receives. Real transformers on the other hand are not 100%

efficient and at full load, the efficiency of a transformer is between

94% to 96% which is quiet good. For a transformer operating with a

constant voltage and frequency with a very high capacity, the efficiency

may be as high as 98%. The efficiency, η of a transformer is given as:

Transformer Efficiency

where: Input, Output and Losses are all expressed in units of power.

Generally when dealing with transformers, the primary watts are called “volt-amps”, VA to differentiate them from the secondary watts. Then the efficiency equation above can be modified to:

It is sometimes easier to remember the relationship between the

transformers input, output and efficiency by using pictures. Here the

three quantities of VA, W and η

have been superimposed into a triangle giving power in watts at the top

with volt-amps and efficiency at the bottom. This arrangement

represents the actual position of each quantity in the efficiency

formulas.

Transformer Efficiency Triangle

and transposing the above triangle quantities gives us the following combinations of the same equation:

Then, to find Watts (output) = VA x eff., or to find VA (input) = W/eff., or to find Efficiency, eff. = W/VA, etc.

Transformer Basics Summary

Then to summarise this transformer basics tutorial. A Transformer

changes the voltage level (or current level) on its input winding to

another value on its output winding using a magnetic field. A

transformer consists of two electrically isolated coils and operates on

Faraday’s principal of “mutual induction”, in which an EMF is induced in

the transformers secondary coil by the magnetic flux generated by the

voltages and currents flowing in the primary coil winding.

Both the primary and secondary coil windings are wrapped around a

common soft iron core made of individual laminations to reduce eddy

current and power losses. The primary winding of the transformer is

connected to the AC power source which must be sinusoidal in nature,

while the secondary winding supplies power to the load.

We can represent the transformer in block diagram form as follows:

Basic Representation of the Transformer

The ratio of the transformers primary and secondary windings with

respect to each other produces either a step-up voltage transformer or a

step-down voltage transformer with the ratio between the number of

primary turns to the number of secondary turns being called the “turns

ratio” or “transformer ratio”.

If this ratio is less than unity, n < 1 then NS is greater than NP and the transformer is classed as a step-up transformer. If this ratio is greater than unity, n > 1, that is NP is greater than NS,

the transformer is classed as a step-down transformer. Note that single

phase step-down transformer can also be used as a step-up transformer

simply by reversing its connections and making the low voltage winding

its primary, and vice versa as long as the transformer is operated

within its original VA design rating.

If the turns ratio is equal to unity, n = 1

then both the primary and secondary have the same number of windings,

therefore the voltages and currents are the same for both windings.

This type of transformer is classed as an isolation transformer as

both the primary and secondary windings of the transformer have the same

number of volts per turn. The efficiency of a transformer is the ratio

of the power it delivers to the load to the power it absorbs from the

supply. In an ideal transformer there are no losses so no loss of power

then Pin = Pout.

In the next tutorial to do with Transformer Basics, we will look at the physical Construction of a Transformer and see the different magnetic core types and laminations used to support the primary and secondary windings.

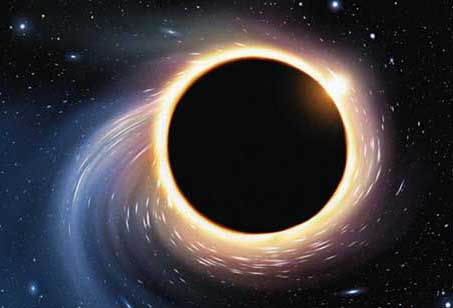

Though we cannot "see" a black hole itself (since not even light can

escape the hole's gravitational field), we may see the hole's effects on

nearby matter. For example, if gas from a nearby star were sucked

towards the black hole, the intense gravitation

al energy would heat the gas to millions of degrees. The resulting X-ray

emissions could point to the presence of the black hole.

Though we cannot "see" a black hole itself (since not even light can

escape the hole's gravitational field), we may see the hole's effects on

nearby matter. For example, if gas from a nearby star were sucked

towards the black hole, the intense gravitation

al energy would heat the gas to millions of degrees. The resulting X-ray

emissions could point to the presence of the black hole.